DOW FILMTEC™ XLE-440 High Productivity Low-Energy Brackish Water RO Element

The lowest pressure DOW FILMTEC™ RO Element

DOW FILMTEC XLE-440 Elements are ideal for reverse osmosis plant managers and operators dealing with controlled pre-treatment and seeking high-quality permeate water at low operating costs. FilmTec XLE-440 minimizes equipment CAPEX in designs with savings in elements and pumping due to the 440 ft2 active area. XLE-440 also delivers the most effective cleaning performance, robustness and durability due to its widest cleaning pH range (1-13) tolerance and the support of FilmTec technical representatives

DOW FILMTEC Brackish Water Reverse Osmosis 8" Elements can separate salts from water and are produced with an automated fabrication process that ensures precision, consistency, and reliability. They are ideal for use in large-scale industrial and municipal water treatment systems that produce greater than approximately 10 gpm (2300 L/h) of permeate. Our RO membranes build on a tradition of leadership in the thin-film composite membrane industry and meet today's challenges for higher rejection using less energy and resisting foulants in challenging waters.

Dow inclucdes one coupler part number PV-IN811LE (259171) with each element. Each coupler includes two 3-912 EPR o-rings.

DOW FILMTEC XLE-440 is FDA – 21 CFR 177.2550; Food and Drug Administration Compliant.

|

|

Specifications for XLE-440

|

|

|

|

FilmTec Product: |

XLE-440 |

|

FilmTec Part Number: |

101060 |

|

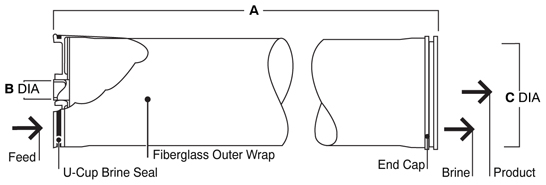

Size (Approximate): |

8" Dia. x 40"L |

|

Flow Rate: |

14,000 gpd (53 m³/d) |

|

Applied Pressure: |

125 psig (8.6 bar) |

|

Stabilized Salt Rejection: |

99.0% |

|

Minimum Salt Rejection: |

98.0% |

|

Single Element Recovery: |

15% |

|

End Style: |

Standard Flush Cut, 1.5" ID |

|

Exterior: |

Hard Shell Fiberglass |

|

Active Surface Area: |

440 Sq. Ft. |

|

Feed Spacer: |

28 mil |

Membrane Type:

|

Polyamide Thin-Film

Composite |

|

|

|

Permeate flow and salt rejection based: 2,000 ppm NaCl feed stream, 77°F, 15% recovery, 125 psig.

Operating Limits for XLE-440

|

|

|

|

Maximum Operating Temperature: |

113°F (45°C) |

|

Maximum Operating Pressure: |

600 psig (41 bar) |

|

Maximum Pressure Drop: |

15 psig (1 bar) |

|

pH Range, Continuous Operation*: |

2-11 |

|

pH Range, Short-Term Cleaning**: |

1-13 |

|

Maximum Feed Silt Density Index: |

SDI 5 |

|

Fere Clorine Tolerance***: |

<0.1ppm |

|

|

|

*Maximum temperature for continuous operation above pH 10 is 95°F

**Refer to cleaning guidelines.

***Under certain conditions, the presence of free chlorine and other oxidizing agents will cause premature membrane failure. Since oxidation damage is not covered under warranty, Dow recommends removing residual free chlorine by pretreatment prior to membrane exposure.

|